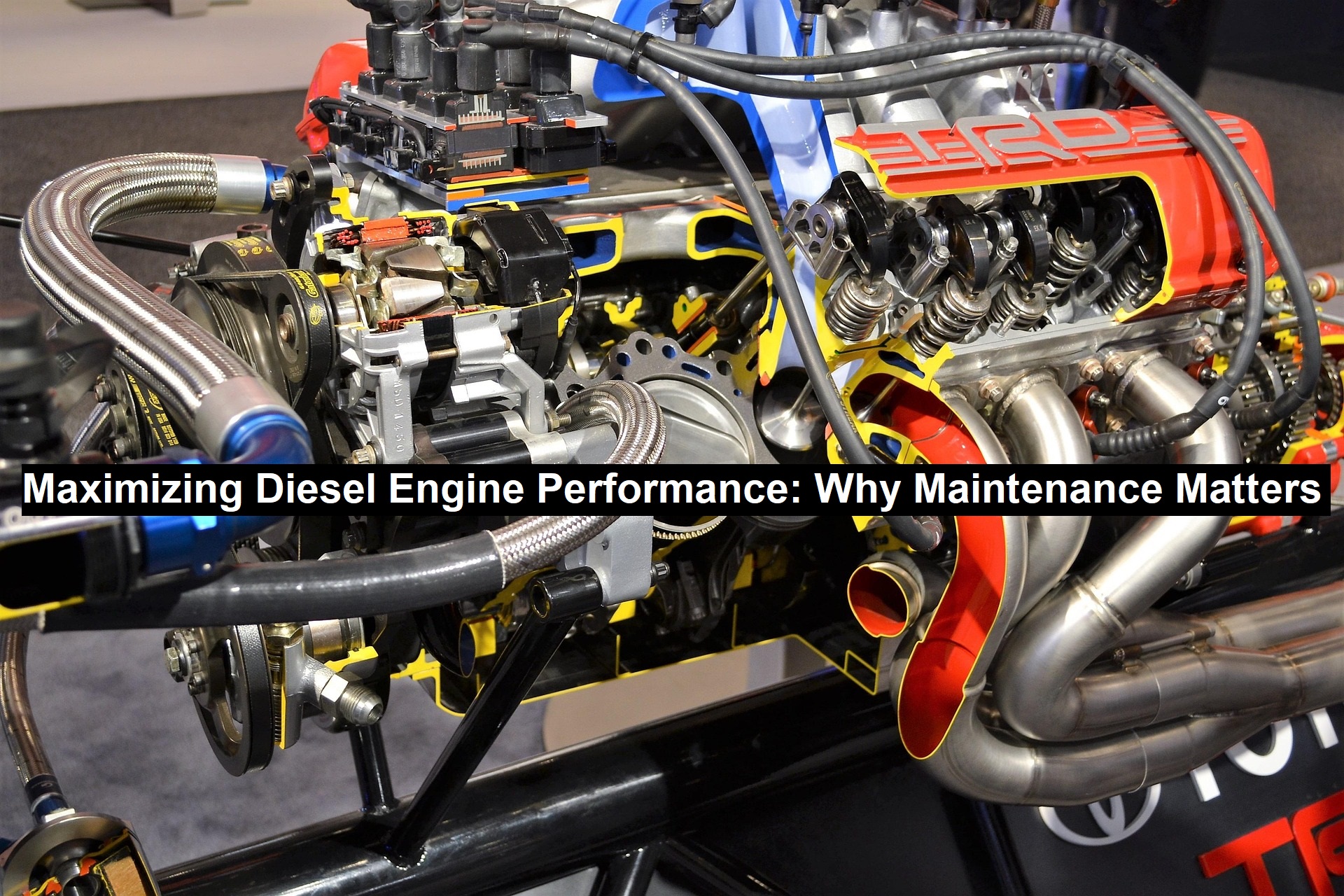

Maximizing Diesel Engine Performance: Why Maintenance Matters

Diesel engines are widely recognized for their durability and dependability, driving industries like transportation, construction, and agriculture. However, these engines require consistent maintenance to maintain their performance and longevity. Without proper care, even the most robust diesel engines can suffer from reduced efficiency, costly repairs, and premature failure. Understanding the importance of diesel engine maintenance is crucial for extending engine life and ensuring optimal performance.

The Special Demands of Diesel Engines

Unlike gasoline engines, diesel engines operate using compression ignition, which creates higher internal pressures and temperatures. This unique combustion process puts more strain on engine components, making regular maintenance essential. By performing routine maintenance, you help minimize wear on critical parts, ensure efficient combustion, and maintain proper lubrication for the moving components.

Diesel engines are often used in heavy-duty applications, such as towing, hauling, and continuous operation. While these engines produce more torque, the extra load demands frequent checks to prevent premature wear on parts like fuel injectors, turbochargers, and cooling systems. A well-maintained engine can continue to perform efficiently despite the added strain.

Read: Benefits of Having Your Car Washed Regularly

Challenges Faced by Diesel Engine Maintenance

One of the most common maintenance issues with diesel engines is carbon buildup. Soot and carbon deposits can accumulate in key areas like the exhaust gas recirculation (EGR) valve and intake manifolds, leading to reduced fuel efficiency and engine performance. Regular decarbonization treatments are vital to prevent these problems and ensure the engine continues to run smoothly.

Another challenge is water contamination in the fuel system. Diesel fuel naturally attracts water, which can lead to microbial growth inside the tank and cause damage to fuel injectors or pumps. Using water separators and changing fuel filters as recommended can help prevent costly damage and ensure the fuel system stays in good condition.

New Innovations in Diesel Engine Maintenance

Thanks to technological advancements and performance products, maintaining diesel engines has become more efficient than ever. Diagnostic tools allow mechanics to quickly detect issues and resolve them before they turn into major problems. Many diesel-powered vehicles now come equipped with onboard telematics systems that provide real-time performance data, helping operators stay ahead of maintenance needs and reduce downtime.

Additionally, new synthetic oils and advanced fuel additives offer enhanced lubrication and reduce the buildup of deposits, providing better protection for vital components. These innovations extend service intervals and boost the overall performance of diesel engines.

Conclusion

Proper maintenance is key to ensuring your diesel engine remains efficient, reliable, and cost-effective over the long term. By addressing common challenges and embracing modern technology, you can maximize engine performance and extend its service life.

For more tips on diesel engine maintenance, please check out the accompanying resource.

Diesel-Engine-Performance